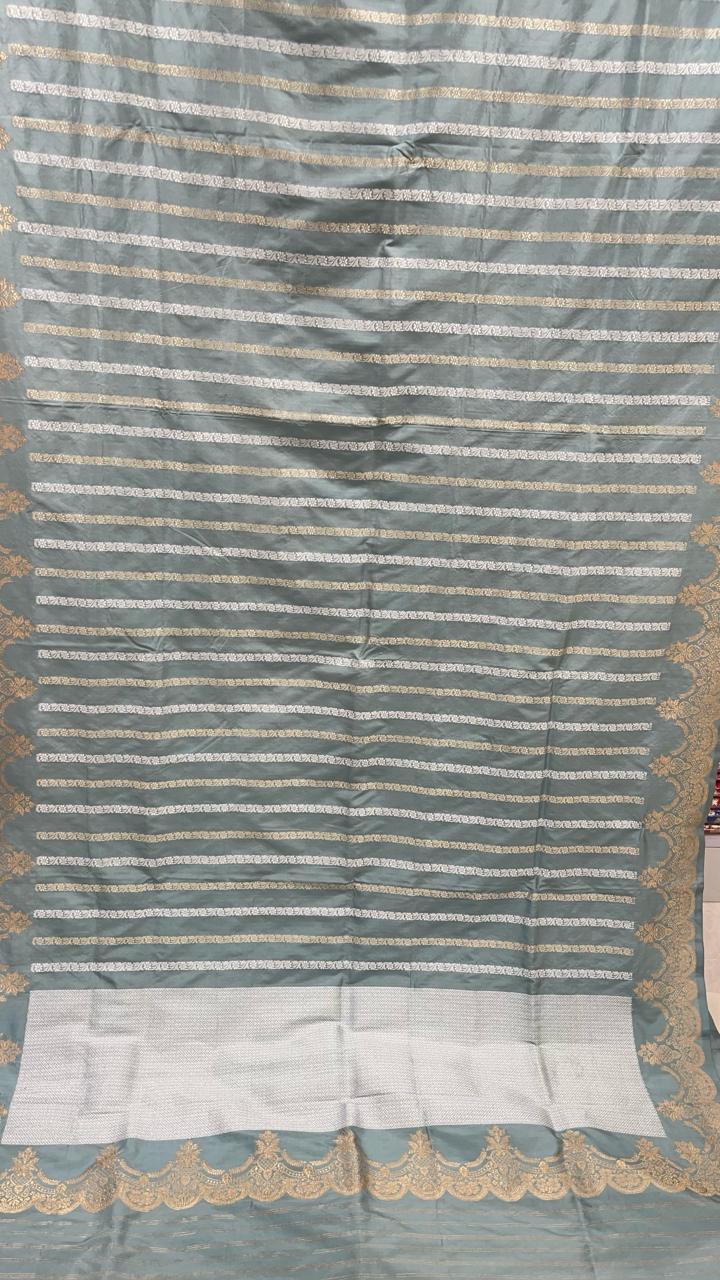

Faishana Pure Silk Handloom Grey Katan Silk Sona Rupa Zari Kadhwa Strip with Kadhwa Zari Border and Grey Blouse

Faishana Pure Silk Handloom Grey Katan Silk Sona Rupa Zari Kadhwa Strip with Kadhwa Zari Border and Grey Blouse

SKU:PURESILK_26 AB

Couldn't load pickup availability

Low stock: 1 left

The Faishana present Pure Handloom Katan Silk grey saree features intricate Kadhwa Sona Rupa Zari stripes on the body and a matching kadhwa gold border. The saree comes with a grey kadhwa blouse that complements the overall look. Made with pure silk, this handloom saree is luxurious and elegant, perfect for special occasions or festive events. Stand out in style with this stunning grey saree from Faishana. You can find this saree at the Faishana store located at Mint House Nadesar, Andhrapul, and it is available for purchase online through their website, www.faishana.in.

Faishana presents a sophisticated Pure silk Handloom Katan Grey Saree adorned with a Kadhwa strip design and complemented by a Kadhwa Border. This exquisite saree also includes a Grey Kadhwa Blouse, adding to its elegance and completeness.

Katan handloom pure silk sarees are considered expensive due to several factors that contribute to their quality, craftsmanship, and cultural significance:

1. High-Quality Silk: Katan silk is known for its superior quality. It is made from pure silk fibers, which are carefully selected for their strength, smooth texture, and natural sheen. The use of high-quality silk alone adds to the cost of the saree.

2. Handloom Weaving: These sarees are handwoven on traditional looms by skilled artisans. Handloom weaving is a labor-intensive process that requires meticulous attention to detail and can take several weeks or even months to complete, depending on the complexity of the design. The craftsmanship involved in handloom weaving is highly valued, contributing to the higher cost of the saree.

3. Traditional Techniques: Katan sarees often incorporate traditional weaving techniques such as Kadhwa and Meenakari. Kadhwa involves weaving intricate motifs into the fabric using a supplementary weft technique, while Meenakari adds further embellishment with metallic threads. These techniques require specialized skills and craftsmanship, which are passed down through generations of weavers.

4. Exclusivity and Rarity: Each Katan handloom pure silk saree is unique due to the handcrafted nature of its production. The designs, motifs, and color combinations are often exclusive and may not be replicated exactly in mass-produced sarees. This exclusivity adds to the saree's value and appeal.

5. Cultural Heritage: Katan sarees are deeply rooted in Indian cultural heritage, particularly in regions like Varanasi (Benaras) where they have been woven for centuries. They are often worn on special occasions such as weddings, festivals, and ceremonies, symbolizing tradition, elegance, and status.

6. Demand and Market Factors: The demand for authentic handloom sarees, especially those made from high-quality silk and showcasing intricate designs, contributes to their higher price. Additionally, factors such as inflation, raw material costs, and the economic conditions of the weaving communities also influence pricing.

In summary, the expense of Katan handloom pure silk sarees is justified by their superior quality silk, intricate craftsmanship, traditional weaving techniques, cultural significance, and exclusivity. These sarees are not just garments but pieces of art that embody centuries-old weaving traditions and craftsmanship excellence. Coloring or dyeing Pure Katan Silk is a meticulous process that requires precision and expertise to ensure the fabric retains its luxurious texture and vibrant color. Here's a detailed breakdown of how Pure Katan Silk is dyed:

1. Preparation of the Silk

- Scouring: The silk is first cleaned to remove any impurities such as sericin (a natural gum) and other substances. This is done by washing the silk in a mild soap or detergent solution.

- Bleaching: If the silk needs to be a very light or bright color, it may be bleached. This involves treating the silk with a gentle bleaching agent to lighten its natural color.

2. Choosing the Dye

- Natural Dyes: Derived from plants, insects, or minerals, natural dyes are often used for their rich, organic colors. Examples include indigo (blue), madder root (red), and turmeric (yellow).

- Synthetic Dyes: These dyes are man-made and provide a wider range of colors and consistency. They are often used for their ease of application and colorfastness.

3. Dyeing Process

- Dissolving the Dye: The chosen dye is dissolved in water. For natural dyes, the dye material is boiled in water to extract the color, while synthetic dyes are mixed as per the manufacturer’s instructions.

- Preparing the Dye Bath: The dye solution is poured into a large dye bath. The temperature and pH of the dye bath are carefully controlled to ensure the silk absorbs the dye evenly.

4. Immersion and Dyeing

- Soaking the Silk: The prepared silk fabric is soaked in water to ensure it is evenly wet before dyeing. This helps the dye penetrate the fibers more uniformly.

- Immersing in Dye Bath: The wet silk is then immersed in the dye bath. The fabric is stirred continuously to ensure even dye absorption. The time the silk spends in the dye bath varies depending on the desired color intensity.

- Heat Setting: For some dyes, especially synthetic ones, heat is applied to set the dye. The dye bath is heated to a specific temperature, and the silk is simmered for a set period.

5. Post-Dyeing Treatment

- Rinsing: After the desired color is achieved, the silk is removed from the dye bath and rinsed thoroughly in cold water to remove any excess dye. Multiple rinses may be necessary until the water runs clear.

- Fixing the Color: To ensure the color is fast, a fixing agent or mordant may be used. For natural dyes, substances like alum or vinegar are commonly used as mordants. For synthetic dyes, specific chemical fixatives are used.

- Final Washing: The silk is given a final wash with a mild detergent to ensure all residues are removed and then rinsed thoroughly.

6. Drying and Finishing

- Drying: The dyed silk is carefully hung to dry in a shaded area away from direct sunlight to prevent color fading.

- Finishing: Once dry, the silk may undergo a finishing process where it is steamed and ironed to restore its smooth, luxurious texture.

Summary

Dyeing Pure Katan Silk is a complex process that involves careful preparation, precise control of dye conditions, and thorough post-dyeing treatments. Whether using natural or synthetic dyes, the aim is to achieve vibrant, even color while maintaining the fabric's luxurious feel and sheen. Each step, from preparation to finishing, is crucial to ensure the quality and beauty of the dyed silk fabric.

Creating a Pure Katan Silk Kadhua Saree is a labor-intensive and meticulous process that can take several weeks to months. The time required depends on various factors, including the complexity of the design, the skill of the weaver, and the specific techniques used. Here’s a detailed breakdown of the time involved in each stage of the process:

1. Designing

- Conceptualization and Drawing: 1-2 weeks

- Designers spend time conceptualizing the design, drawing detailed motifs, and finalizing the layout.

2. Preparing the Yarn

- Silk Thread Selection and Dyeing: 1-2 weeks

- Selecting high-quality Katan silk threads.

- Dyeing the threads in the required colors, followed by drying and reeling.

3. Setting Up the Loom

- Warping and Drafting: 1 week

- Stretching and winding the dyed threads onto the loom.

- Threading the warp threads through the heddles and reed.

4. Weaving

- Main Weaving (Kadhua Technique): 4-8 weeks

- Using the Kadhua technique to weave intricate floral motifs and incorporate Sona Rupa zari.

- The exact time depends on the complexity of the design and the number of motifs.

5. Finishing

- Cutting and Hemming: 1-2 days

- Cutting the saree from the loom and hemming the edges.

- Washing and Polishing: 3-5 days

- Washing to remove residual dyes and polishing to enhance the silk’s luster.

- Quality Check: 1-2 days

- Thorough inspection to ensure there are no weaving defects.

6. Final Touches and Packaging

- Final Touches: 1-2 days

- Adding any additional embellishments and ensuring the saree is ready for sale.

- Packaging: 1 day

- Neatly folding and packaging the saree for delivery.

Total Time

The entire process, from conceptualization to the final packaging, can take approximately 8-14 weeks (2-3.5 months). This timeline can vary depending on the complexity of the design, the efficiency of the artisans, and any additional customizations requested by the buyer.

Summary

Creating a Pure Katan Silk Kadhua Saree is a time-consuming process that involves careful planning, skilled weaving, and meticulous finishing. The intricate Kadhua technique and the use of Sona Rupa zari add to the time required, making each saree a unique piece of art that reflects the craftsmanship and dedication of the weavers.

Note:- For customer convenience and satisfaction, Faishana offers video call facilities to showcase their sarees directly to customers. They can be contacted via WhatsApp at +91-8808321678 and +91-7654321678 for sharing videos, images, and further inquiries. This Product is Handwoven, there may be some minor irregularities that are a characteristic feature of genuine Handmade Products but that makes a woven saree unique. We pledge to cease child labor. This product ships worldwide.

Brand Name:- Faishana Belong To Banaras By Powertech Infraenergy Pvt Ltd

Product Dimension:- Saree Length:- 5.5 Mtrs, Unstitched Blouse Length:- 0.80 Mtrs (attached)

Fall & Pico:- Extra Rs. 350/-

Tassels:- We take no charges for adding tassels to the sarees but it takes 2 to 4 days to make your product ready with tassels

Manufactured & Marketed By:- M/s Powertech Infraenergy Private Limited

Country of Origin:- India

Mint House Store:- M/S Powertech Infraenergy Pvt Ltd, S 19/7-X-3, Varuna Bridge, Mint House, Nadesar, Varanasi, Uttar Pradesh-221002, India Contact No:- +91-7654321678, +91-8808321678

Andhrapul Store:- M/S Powertech Infraenergy Pvt Ltd, S 14/ 18-1 KH-1K, 1st Floor, Raniya Mahal, Andhrapul, Teliyabagh, Varanasi, Uttar Pradesh-221002, India Contact No:- +91-7654321678, +91-8808321678

Disclaimer:- Benares, now known as Varanasi, is the oldest continuously inhabited city globally, located in India. Its original name, Kashi, is derived from the Sanskrit words meaning "Light" or "Enlightenment." Varanasi is renowned for its skilled handloom weavers who create intricate designs on fabrics. These designs are unique to their tradition and incorporate intricate floral and foliate motifs.

Assured Quality

Assured Quality

Our products consist of good quality raw materials used, which assures you of the desired quality product.

Ready to Ship

Ready to Ship

Expertly Cross-Checked Products Ready to Ship from Our Warehouse.

Exchange & Returns

Exchange & Returns

Shop with confidence! We take customer satisfaction seriously. That's why we offer a 3-day, hassle-free return policy. No worries if something isn't quite right. Simply bring it back in its original packaging within 5 days, and we'll happily exchange it for something you love or give you store credit for a future purchase. The choice is yours! For complete details, check out our return policy. But for now, happy shopping!

Share

100% Authentic Products | 100% Secure Payments

Elevate your living space with the luxurious touch of our handcrafted artifacts and woven products. Experience the essence of craftsmanship.